The first question you may be asking: “Why Wade’s Extruder?” There are so many extruder designs going (check out http://reprap.org/wiki/Extruder ), why this one in particular? The answer is quite simple – because the RP'ed parts came with my Metric Prusa Kit. I figured I might as well go with the one I already had the parts for, and I can always choose a different design, or modify this one later.

Before commencing the build, I downloaded and printed Gary Hodgson’s visual guide: http://garyhodgson.com/reprap/wades-geared-extruder-visual-instructions/ and watched the assembly videos on the Wade’s Extruder page http://reprap.org/wiki/Wade%27s_Geared_Extruder . However, I was still a little apprehensive – I had never heard of a “Hobbed Bolt” before, let alone made my own. My kit http://julianh72.blogspot.com/2011/08/my-parts-list.html came with all the parts I needed (apart from the Stepper Motor, which I had purchased separately http://julianh72.blogspot.com/2011/08/my-parts-list-stepper-motors.html ). First task according to the visual instructions was to “Hobb” the bolt, which acts as the friction drive for the filament extruder. The Wikipedia entry on “Hobbing” http://en.wikipedia.org/wiki/Hobbing did not fill me with any more confidence: “Hobbing is a machining process for making gears, splines, and sprockets on a hobbing machine, which is a special type of milling machine. The teeth or splines are progressively cut into the workpiece by a series of cuts made by a cutting tool called a hob.” What the …?! I don’t have a “special type of milling machine”; all I have is a vice and a drill – how is this ever going to work?!

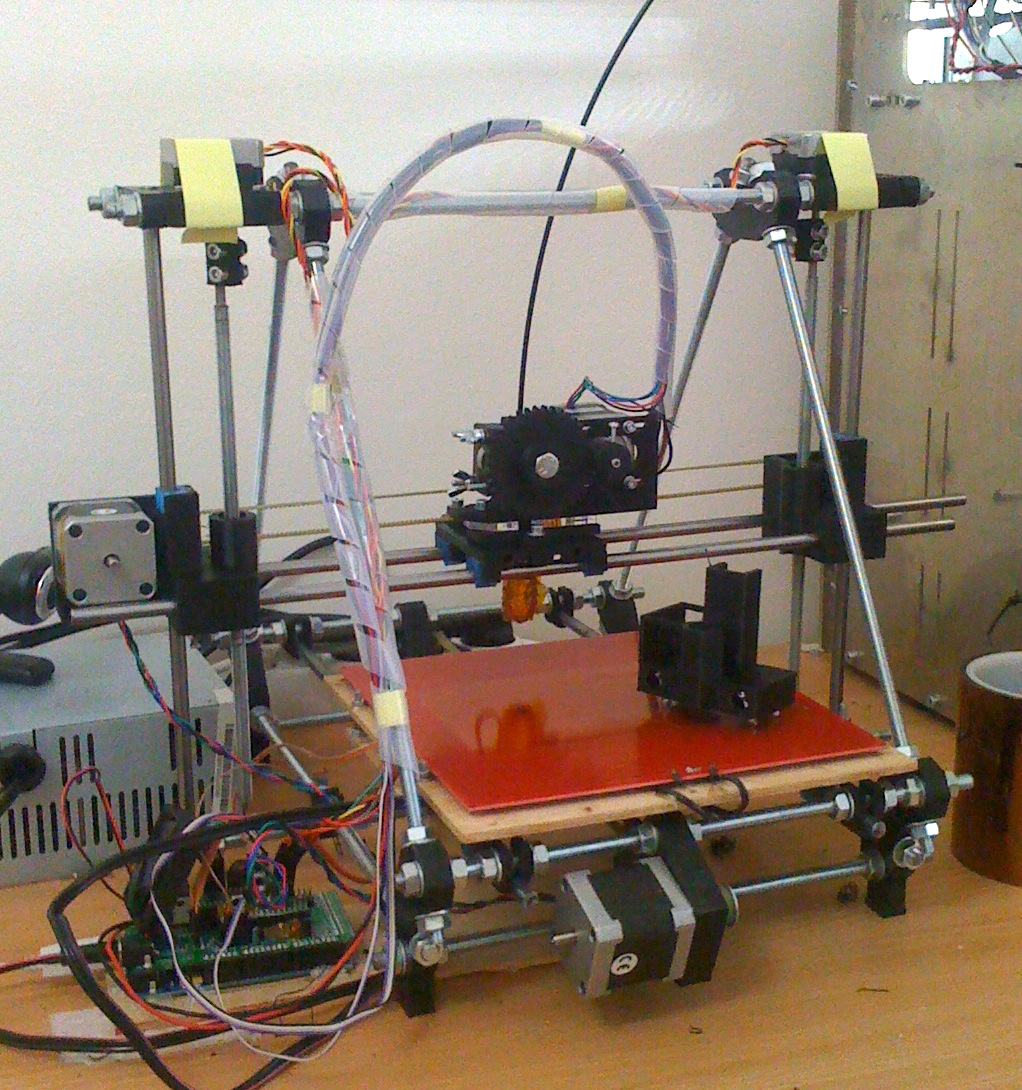

I did a trial assembly of the extruder, main gear, bearings and bolt, to mark the location where the friction grooving would be required to drive the filament through. Following the video instructions here: http://reprap.org/wiki/Wade%27s_Geared_Extruder#How_to_build_it , I clamped a narrow “rat-tail” file in my vice, and fitted the bolt in my drill (protecting the threads with some insulation tape), and a couple of minutes later had a nice rounded groove in the shank of the bolt. I then fitted two bearings onto the bolt, and clamped them into the vice (protecting the bearings with some insulation tape) to allow the bolt turn easily while I cut a thread in the groove with an M3 thread tapper. Two more minutes work, and I had what looked like a nice “Hobbed Bolt” (to my untrained eyes, anyway).I then assembled the whole extruder body assembly. Note for the uninitiated: the visual instructions say at Step 4: “(Optional) You may wish to insert the x-carriage bolt now, as this may be difficult once the idler is in place.” Trust me – this is NOT optional – there is simply no way the X-Axis Carriage bolts are going to go in later – do it NOW! (My set-up has two bolts to mount on the X-Carriage, one of which is mounted under the Motor, and the other goes under the Idler Block. The bolt under the Motor MUST be installed before the motor; the bolt under the Idler Block can be installed later, but you might as well get it over and done with now.

I initially assembled the Idler Block using 4 M4 washers on each bolt, as suggested in the Visual Instructions. The springs supplied with my kit were too long to press down to fit over the bolts with the washers installed, or indeed, without any washers. This was easily fixed by cutting two springs in half and installing half-length springs over each of the bolts, but they would only fit if I removed all of the washers. I am actually not sure what the washers are for – the guide says "If you add 3 or 4 M4 washers on each bolt before you put the idler block on, it will reduce the idler block travel when loading new filament, making loading new filament much easier", but the whole thing went together better for me by leaving the washers out, and the springs should allow enough “give” in the Idler Block to allow for loading of new filament – I guess I will find out when I start commissioning!

I then found that when mounting the motor, I had to leave the washers off the motor-mounting bolts that fit under the gear head to get the gear to clear them, and I had to add another M8 washer under the main gear to get it far enough off the face of the extruder body to clear everything.

This in turn meant that I had to cut a new Hobbed groove in the bolt (the extra washer meant that my first groove was now not aligned with the filament feed point) – but I was getting good at “Hobbing” bolts by now, so this was no real problem!

This in turn meant that I had to cut a new Hobbed groove in the bolt (the extra washer meant that my first groove was now not aligned with the filament feed point) – but I was getting good at “Hobbing” bolts by now, so this was no real problem!

I don’t have any 3 mm PLA or ABS filament as yet, but I do have some 2 mm "whipper-snipper" line, and I was really please to discover that when fully assembled, it grips onto the 2 mm filament REALLY strongly, and the whole mechanism is very smooth, and pulls the filament through very nicely. Hopefully, it will be just as smooth under electric power, working with 3 mm filament!

I actually find this quiet extraordinary – that it is possible to design and fabricate a complex high-precision assembly like this, that a complete novice like me can build. Think about this: the extruder motor has 200 steps per revolution, and with 1/16 micro-stepping, this makes 3,200 controllable micro-steps per revolution. The pinion gear has 11 teeth, and the big gear has 39, and is driving an 8 mm diameter pinch shaft. Each revolution of the motor therefore gives 11/39 of a revolution of the pinch shaft, which is equivalent to feeding 11/39 * pi * 8 = 7.1 mm of filament; each 1/16 controllable micro-step feeds the equivalent of about 2.2 microns of filament – just amazing!

I actually find this quiet extraordinary – that it is possible to design and fabricate a complex high-precision assembly like this, that a complete novice like me can build. Think about this: the extruder motor has 200 steps per revolution, and with 1/16 micro-stepping, this makes 3,200 controllable micro-steps per revolution. The pinion gear has 11 teeth, and the big gear has 39, and is driving an 8 mm diameter pinch shaft. Each revolution of the motor therefore gives 11/39 of a revolution of the pinch shaft, which is equivalent to feeding 11/39 * pi * 8 = 7.1 mm of filament; each 1/16 controllable micro-step feeds the equivalent of about 2.2 microns of filament – just amazing!