OK - so I have been interested in 3D printing since I first saw it in a commercial environment about 10 years ago. I was working on a project for a client who makes electrical components (switches, lights, etc) for the automotive industry. I had to do some Finite Element Analysis (FEA) to check for thermal distortion of a component they were having some problems with; having made some design changes, I went to the factory to discuss my proposed changes. In one day, they took my FEA model, 3D-printed a full-size sample for everyone to handle, made some minor geometry changes to improve its injection moulding characteristics, milled the new moulds on a desktop CNC Mill, and put the new moulds into the injection moulding machine - 5 hours on site, and they were already manufacturing the part (by the thousands!) to my new design. Wow! The possibilities ....

Only problem for me at home was - the cost! I just couldn't justify spending several grand on what was ultimately just a super-geeky toy! But nevertheless, I have been following developments with keen interest over the years, watching and waiting for the price to come down to something more manageable.

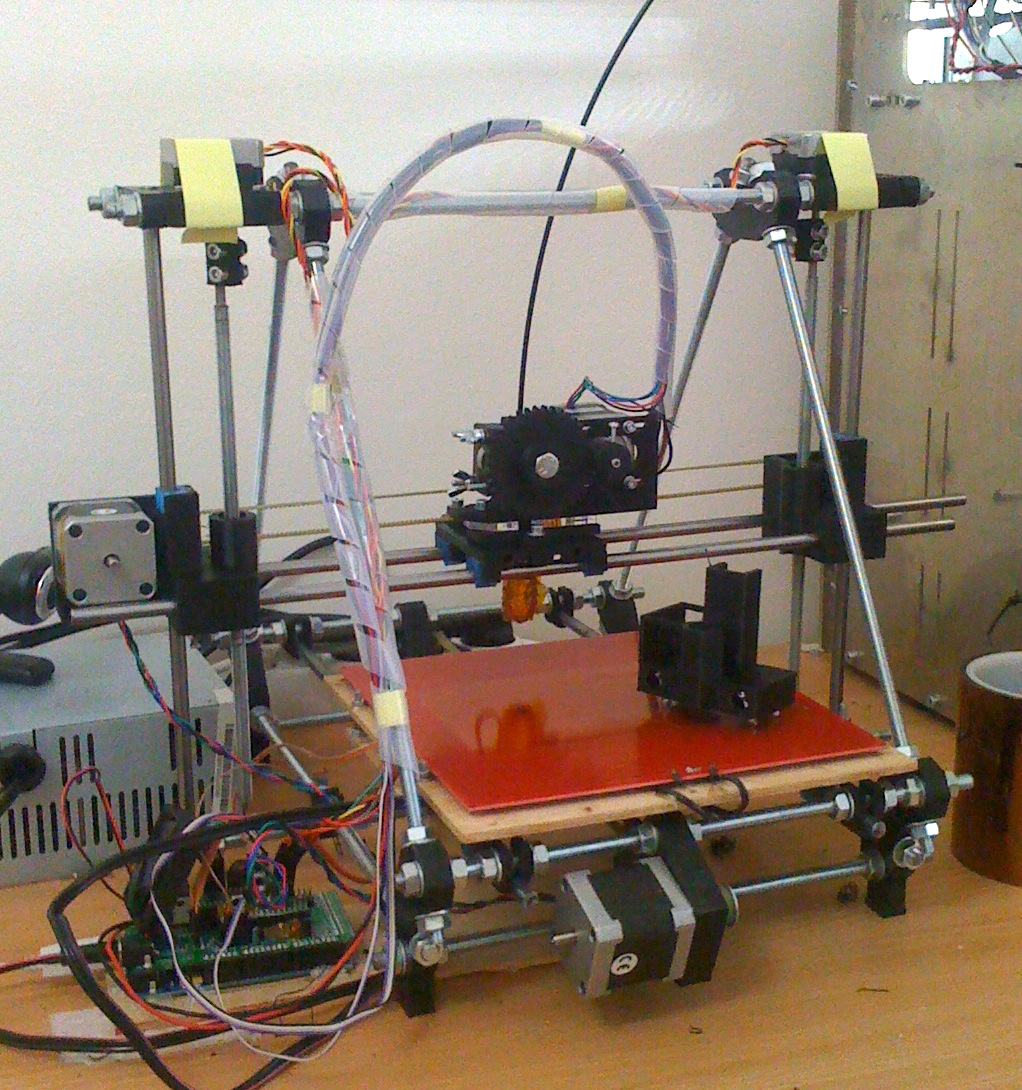

And then I found out about the RepRap Mendel Prusa http://reprap.org/wiki/Prusa:

It started to look like I might be able to build something for an outlay of AU$500 or so. Hmmmm .... very interesting!

Anyway, I have decided to bite the bullet, and have a go at building my own Mendel Prusa. I intend to follow the progress here - let's see how I go! I am posting progressive pictures on my DropBox page www.dropbox.com/gallery/19079824/1/Mendel%20Prusa%20Build?h=b8dfe9 , but you will find a more comprehensive discussion on this blog.

gear hobbing machine supports all known formats of metals

ReplyDelete